How much can the linear motor module improve the efficiency of the factory?

2025-04-15

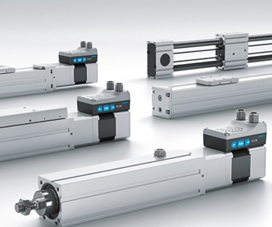

Through technological innovation and structural optimization, linear motor modules can significantly improve the production efficiency of factories. The specific improvement and implementation methods can be seen from the following aspects:

I. Improvement of speed and acceleration

1. Ultra-high operating speed

The speed of traditional transmission equipment (such as lead screws and belt modules) is usually less than 2m/s, while the linear motor module adopts direct drive technology, and the speed can be increased to 2m/s (Misumi) or even 10m/s (Feichuang), and the acceleration can reach 6G. For example, in high-frequency operations such as lithium battery pole cutting or 3C electronic patching, the daily production capacity of Feichuang modules can be increased by more than 30%; the high-speed movement of Misumi modules can greatly shorten the product handling time.

2. Quick response and continuous operation

Misumi modules support 24-hour uninterrupted operation, and adjust the position in real time through a closed-loop control system, reducing the time for traditional equipment to stop and calibrate, and ensuring production continuity.

2. Optimization of precision and stability

1. Micron-level repeatable positioning accuracy

The repeatable positioning accuracy of the linear motor module can reach ±0.002mm (Feichuang) or ±5μm (Misimi), which is much higher than that of traditional equipment, thereby reducing defective products caused by positioning errors and indirectly improving the pass rate and efficiency.

2. Speed fluctuation control

The Feichuang module controls the speed fluctuation within 2% through the grating/magnetic grating feedback system, which is suitable for high-precision scenarios such as semiconductor wafer cutting to ensure production stability.

3. Multi-task processing and space optimization

1. Multi-motor parallel operation

The Misimi module supports up to 4 independently controlled movers on the same axis to achieve multi-station parallel processing. For example, in the assembly of electronic equipment, multi-motor can complete the operation of different components synchronously, saving the sequential operation time of traditional equipment.

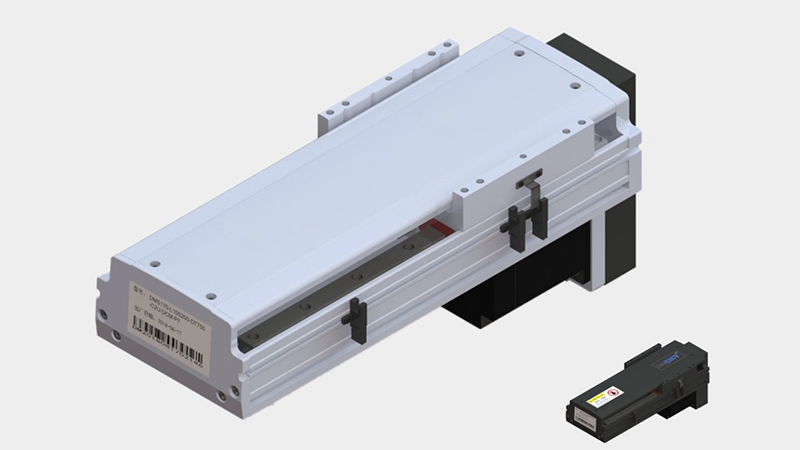

2. Modular design

Modular splicing technology (such as Feichuang's 60-meter ultra-long stroke module) and standardized components (such as Misimi's cross-shaped module) simplify the construction of complex production lines, saving equipment space and debugging time.

IV. Improvement of maintenance cost and lifespan

1. Low friction and long lifespan

The linear motor adopts contactless magnetic suspension technology to reduce mechanical wear, and its lifespan can reach 2.5 times (Misumi) or 50,000 hours (Misumi) of traditional screw modules, significantly reducing maintenance frequency and cost.

2. Fully enclosed design

For complex environments (such as small parts falling problems), fully enclosed modules reduce the risk of failure and ensure production continuity and equipment reliability.

V. Cost control and rapid deployment

1. Economical solution

The price of Misumi's economical module is only 1/3 of that of traditional equipment (starting from about 2,286 yuan). Combined with bulk purchases and economies of scale, the procurement cost is greatly reduced.

2. Quick installation and debugging

The modular design and integrated structure simplify the installation process, save design and debugging time, and accelerate production line deployment.

Comprehensive efficiency improvement

Depending on the application scenario, the efficiency improvement effect of the linear motor module varies significantly:

Speed-sensitive scenarios (such as high-speed handling and cutting): efficiency improvement can reach 30%-50%;

High-precision manufacturing scenarios (such as semiconductors and medical equipment): the defective rate is reduced by more than 50%, indirectly increasing effective production capacity;

Multi-task complex production lines: parallel processing capabilities can improve overall efficiency by 20%-30%.

Linear motor modules provide factories with solutions from single-point efficiency improvement to full-link optimization through comprehensive advantages such as speed, precision, multi-task collaboration, life extension and cost optimization. The specific efficiency improvement needs to be combined with industry characteristics and application scenarios, but generally a 20%-50% leap in production efficiency can be achieved, while reducing comprehensive costs in long-term operations.