Solution

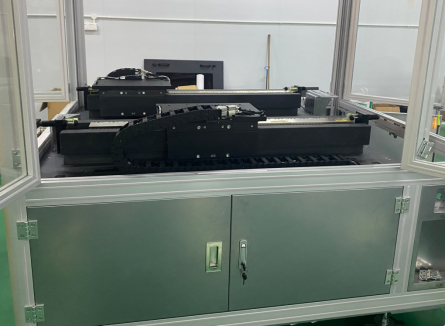

BZD Series Linear Motor Module Solutions

With the continuous development of the manufacturing industry, linear motor modules are being increasingly applied across various sectors. However, as production applications mature, the market's demands for linear motor modules have become more stringent, such as requiring faster delivery times and stricter cost control. It is in this context that Bozhida has introduced the BZD series linear motor modules to meet these market demands.

The BZD series linear motor modules mainly consist of a linear motor, mechanical guide rail, encoder for position feedback, and protective housing. Notably, aside from the connection of the guide rail, there is no contact between the other mechanical components. The motor directly drives the module's mover along the guide rail's direction, with position control achieved through the encoder and photoelectric system.

The advantages of the BZD series linear motor modules lie in their high responsiveness, high precision, high rigidity, long lifespan, high speed, and cost-effectiveness. Since the motor is directly driven, there is no concern about backlash from a lead screw, which significantly improves response speed. Depending on the encoder used, it can achieve a repeatability accuracy of up to ±1μm. The use of mechanical linear guide rails ensures high rigidity across all guiding surfaces. Apart from the contact between the guide rail sliders, there is no other mechanical contact, reducing the risk of module damage caused by mechanical wear. Additionally, the DGC series can meet speed requirements of 3m/s or higher. The use of a profile design greatly reduces machining complexity and material costs, while the standardized design lowers production costs for common parts. The company owns its own machining facility and maintains stock of common components, ensuring quick delivery times.

The BZD series linear motor modules have been widely applied in industries such as photovoltaics, lithium batteries, semiconductors, 3C automation, LCD panels, and optical inspection. They not only provide customers with high-quality products but also effectively reduce production costs and improve overall efficiency. This cost-effective linear motor module is ideal for industries requiring high-speed, high-precision positioning, making it the preferred solution for many customers.

Through the above analysis, our screw module solutions have significant advantages in the fields of industrial automation, precision machining, medical equipment and semiconductor manufacturing, etc. We are able to meet the diversified needs of our customers and provide high-performance, high-reliability products and services. Whether for high-precision machining, high-speed motion control, or long-stroke applications, our solutions bring our customers higher productivity and better product quality.

Linear Motor Modules & Marble Belt Linear Motor Solutions

Functions and Principles of Linear Motors

A linear motor is a device that converts electrical energy directly into linear motion. Its operating principle is based on electromagnetic induction, and it realizes contactless transmission through the electromagnetic force between the stator and the mover. Compared with traditional rotary motors, linear motors have the following core functions:

High-precision positioning: Linear motors adopt closed-loop control system, capable of realizing micrometer or even nanometer positioning accuracy, suitable for high-precision machining and inspection.

High-speed motion: linear motors have fast response speed and high acceleration, which can realize high-speed linear motion, and the highest speed can reach several meters per second.

Non-contact transmission: Linear motor adopts non-contact transmission mode, which reduces mechanical wear and prolongs the service life, and at the same time reduces the maintenance cost.

High Rigidity: Linear motors have a compact structure and high rigidity, capable of withstanding large loads and suitable for high load application scenarios.

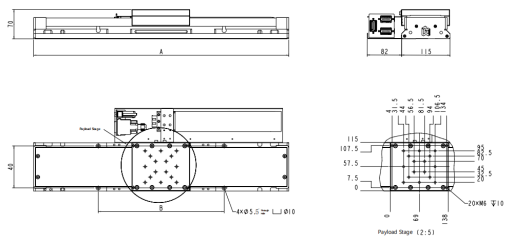

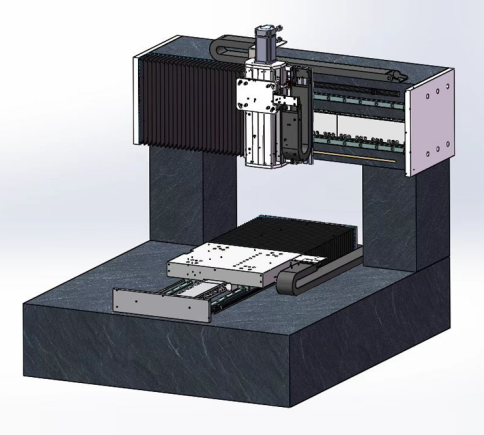

Motor Solution Schematic

Our linear motor modules and marble belt linear motor solutions have significant advantages in the field of high-precision, high-speed linear motion control, which can meet the diverse needs of customers and provide high-performance, highly reliable products and services. Whether it is semiconductor manufacturing, laser processing, or medical equipment and automated production lines, our solutions can bring customers higher production efficiency and better product quality.

Self-positioning

We are a high-tech enterprise specializing in linear motor modules and solutions, dedicated to providing customers with high-performance, highly reliable linear motion control products. Our core advantages are:

Leading technology: We have self-developed linear motor core technology, which can meet the diversified needs of customers.

Customized service: provide customized linear motor module design and solutions according to customer's specific application scenarios.

Full-process support: from product selection, design, manufacturing to after-sales service, provide one-stop service to ensure that customers have no worries.

Products & Services

We provide customers with a comprehensive range of products and services, including:

Linear motor modules: We provide standard and customized linear motor modules to meet the needs of different application scenarios.

Marble platform: adopting high-precision marble platform to ensure the stability and rigidity of the equipment, suitable for high-precision machining and testing.

Control system: Equipped with high-performance motion controller to realize precise motion control and multi-axis linkage.

Technical support: provide the whole process of technical support from selection, installation to commissioning, to ensure that the customer's equipment is quickly put into use.

After-sales service: provide perfect after-sales service, including regular maintenance, troubleshooting and technical training, to ensure the long-term stable operation of customer equipment.

Solution

The marble with linear motor solution we provide combines the high stability of the marble platform and the high precision and high speed characteristics of the linear motor, which is applicable to the field of high-precision processing and inspection. The specific program includes:

1.Marble platform:

Adopting high-precision natural marble material with low coefficient of thermal expansion and high rigidity to ensure the long-term stability of the equipment.

The surface is precisely ground and polished, and the flatness can reach micron level to meet the demand of high-precision machining and inspection.

2. Linear motor module:

Integrated high-precision linear motor module, realizing high-speed and high-precision linear motion, with positioning accuracy up to ±0.1μm.

Adopt contactless transmission mode, reduce mechanical wear and prolong the service life of the equipment.

3.Control system:

Equipped with high-performance motion controller, supporting multi-axis linkage and complex motion trajectory planning.

Provide open interface, easy to integrate with customer's existing system.

Advantage

Our linear motor module with marble belt linear motor solution has the following advantages:

High precision: linear motor module realizes micron-level positioning accuracy to meet the needs of high-precision processing.

High-speed movement: linear motors have fast response speed and high acceleration to improve productivity.

High stability: Marble platform provides high stability and rigidity to ensure long-term stable operation of the equipment.

Non-contact transmission: reduce mechanical wear and tear, extend the service life of the equipment and reduce maintenance costs.

Customized design: according to customer needs, provide customized linear motor module design to meet diversified needs.

Selling points and unique advantages

Leading technology: with self-developed linear motor core technology, to ensure product performance ahead of the industry level.

Cost-effective: Provide competitive price while ensuring high performance to create greater value for customers.

One-stop service: Provide one-stop solution from design, manufacturing to after-sales service to ensure that customers have no worries.

Rapid response: provide rapid response technical support and after-sales service to ensure that the customer's equipment is quickly put into use and long-term stable operation.

← Prev Post

Next Post →