Solution

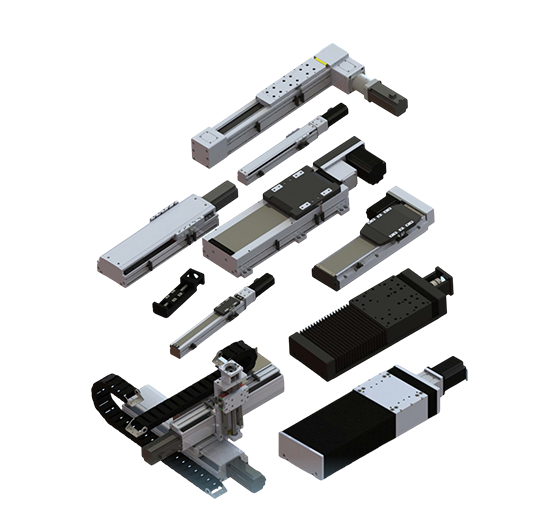

CUSTOM ENGINEERED MOTION SYSTEMS

Our custom motion systems are precision engineered to your exact needs.

From a customized product to a complete motion subsystem, BOSTAR has the industry-leading expertise to engineer precision into your process.

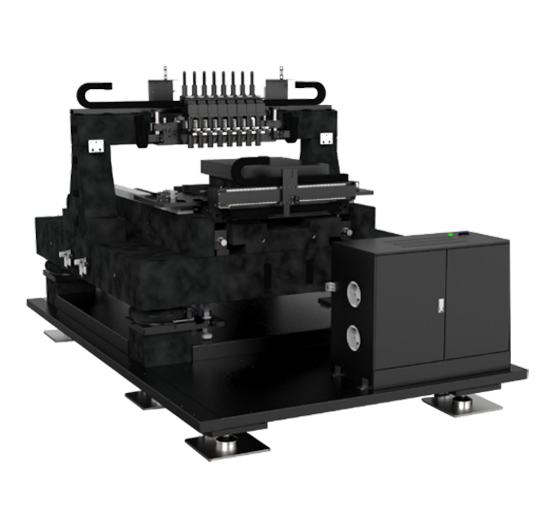

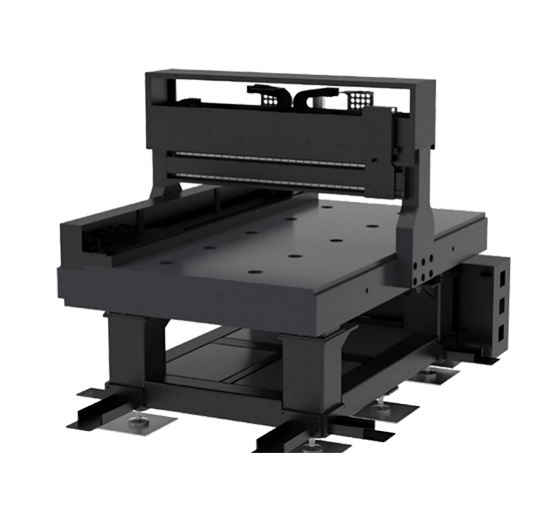

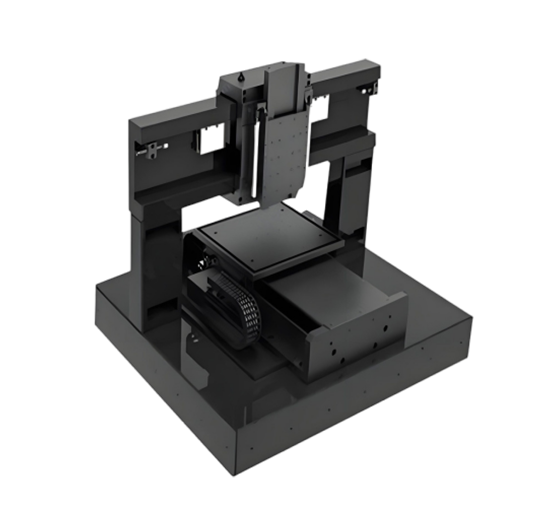

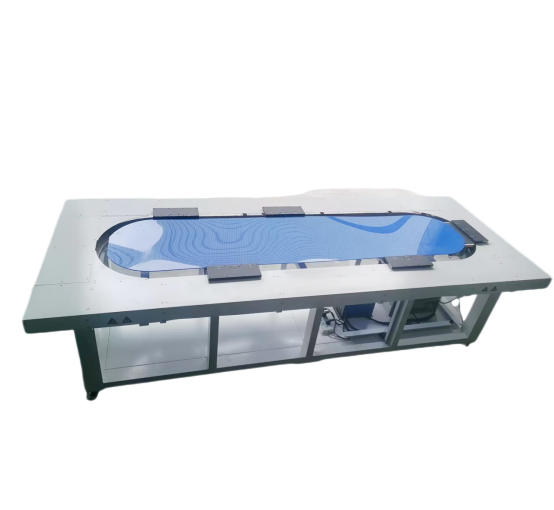

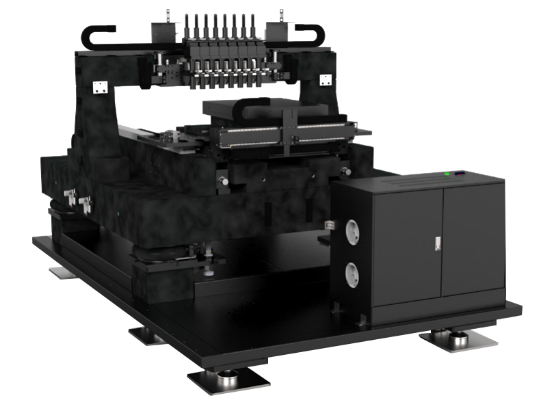

The granite moving-beam/fixed-beam gantry motion platform and the granite motion platform.

BOSTAR launched it's latest masterpiece—the granite moving-beam/fixed-beam gantry motion platform and the granite motion platform. The release of these two platforms has undoubtedly added another milestone to Bozhida’s achievements in the precision machinery industry. The granite moving-beam/fixed-beam gantry motion platform, with its outstanding stability and high-precision motion performance, has garnered widespread attention both within and outside the industry.

Maintain a Competitive Advantage

Our precision motion systems are engineered to get the most out of your machine and process, keeping you ahead of the competition.

Reduce Total Cost of Ownership

Leverage our motion expertise so you can focus on optimizing your process to reduce overall costs and keep your bottom line healthy.

Minimize Technical Risk

Our unmatched depth and breadth of experience means your motion system runs flawlessly and performs at the highest levels – consistently.

High dynamic performance XY adopts full wrap-around air-float guideway, good stability, high precision zero expansion grating feedback, low expansion coefficient, less affected by temperature drift Z-axis uses magnetic spring to balance the load, customizable stroke, size and cable can be customized according to customer's requirements

Application Field

Our expertise across and deeply within many industries gives us a solid foundation for building a reliable and successful motion control solution that meets your specific needs.

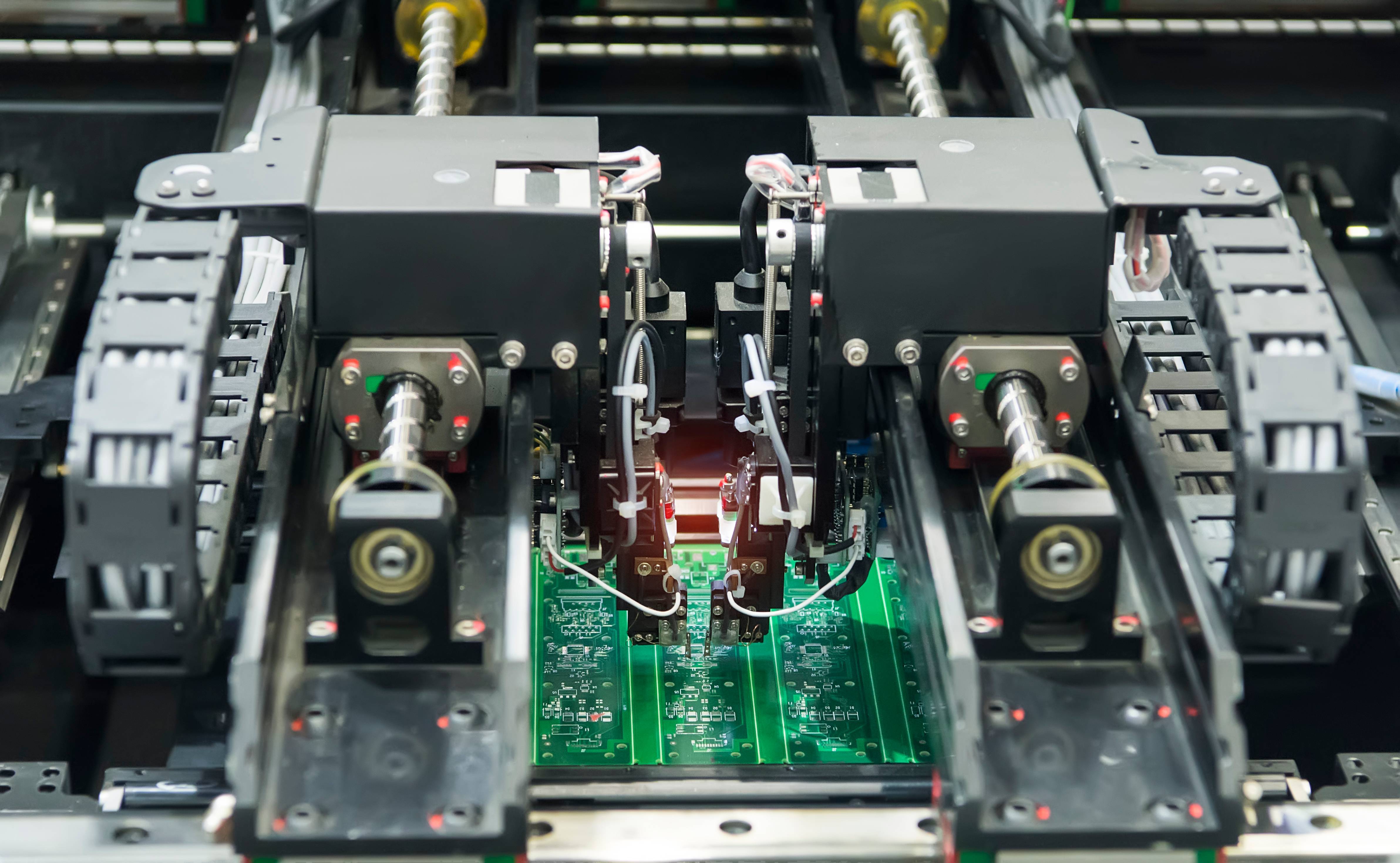

Semiconductor Manufacturing

Photolithography machine: used for nano-scale chip pattern exposure, linear motors achieve ultra-high precision synchronous positioning of the mask stage and wafer stage. Wafer inspection and bonding: high-precision platforms ensure micron-level positioning during wafer defect inspection, cutting and packaging.

Precision measurement and testing

Optical microscope/electron microscope: nanometer-level mobile sample stage, supporting ultra-clear imaging of biological samples or material structures. Coordinate measuring machine (CMM): high-precision platform improves the detection accuracy of complex workpiece geometry.

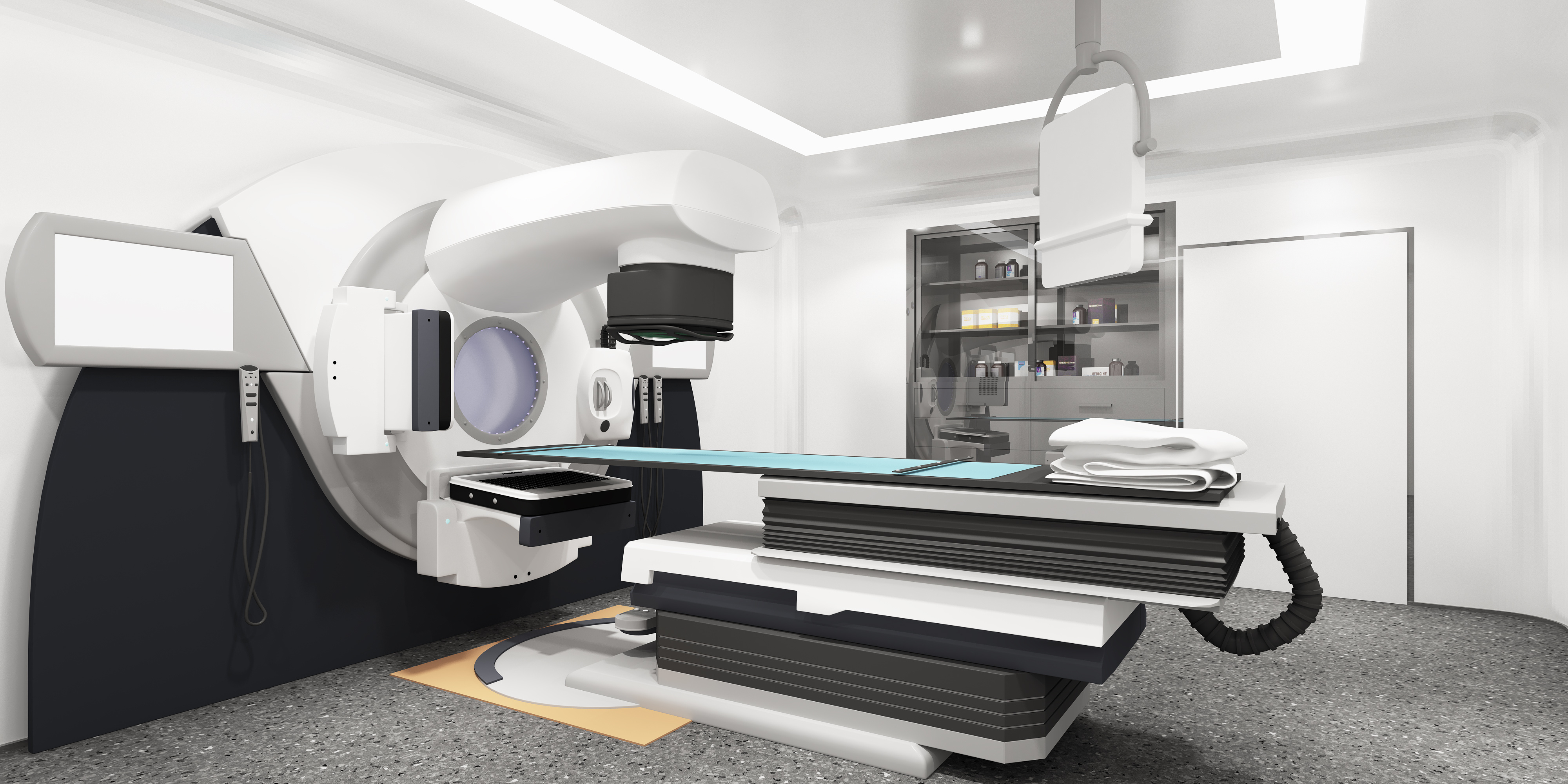

Medical and Biotechnology

Medical imaging equipment (MRI/CT): Linear motors control the smooth movement and precise positioning of the scanning bed. Surgical robots: Such as the da Vinci system, which uses a high-precision platform to achieve sub-millimeter-level operation of minimally invasive surgical instruments.

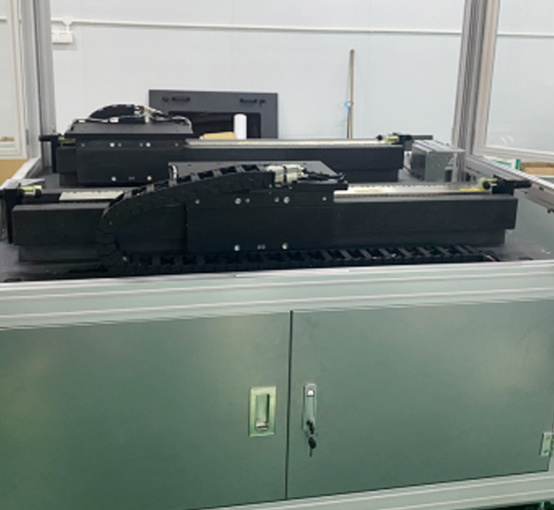

See examples of our work.

Resources

Ready to solve your challenge with tools designed to meet your needs?

Contact Us