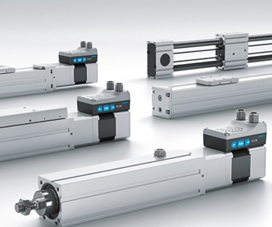

How to maximize the use of screw modules?

2025-04-15

To give full play to the maximum effect of the screw module, it is necessary to comprehensively consider multiple aspects such as design selection, installation and commissioning, use optimization and maintenance. Here are some key suggestions:

1. Reasonable selection and configuration

Choose the type according to the application scenario:

Ball screw: suitable for high-precision, high-speed, and high-load scenarios (such as CNC machine tools and automated production lines).

Trapezoidal screw: suitable for low-speed, light-load, and low-cost scenarios (such as manual adjustment devices).

Matching lead and load:

The larger the lead, the faster the speed, but requires greater torque; the smaller the lead, the higher the accuracy, but the speed is limited.

Calculate the rated dynamic/static load of the screw according to the load to avoid shortening the life due to overload.

Motor selection:

Servo motors are suitable for high dynamic response and closed-loop control, and stepper motors are suitable for low-cost open-loop control.

Ensure that the motor can stably drive the screw through inertia matching and torque calculation.

2. Precision installation and debugging

Installation accuracy control:

Ensure that the screw axis is parallel to the guide rail, and the coaxiality error of the support seats at both ends is ≤0.02mm.

Use a micrometer to calibrate the parallelism of the screw and the guide rail and the verticality of the nut seat.

Preload adjustment:

The ball screw needs to eliminate the axial clearance through a double nut or a clearance adjustment gasket, but the preload should not be too large to avoid heating.

Lubrication and sealing:

Use lithium-based grease or special lubricating oil and replenish it regularly (such as lubrication every 100 hours of operation).

Install a dust cover or sealing ring to prevent dust and chips from entering the nut.

3. Optimize the use conditions

Control the operating parameters:

Avoid long-term overspeed operation (refer to the critical speed limit of the screw).

Optimize the acceleration and deceleration curve to reduce the start-stop impact (such as using the S-type acceleration and deceleration algorithm).

Load management:

Avoid eccentric loads and ensure that the force direction is consistent with the screw axis.

For vertically mounted lead screws, add brakes or counterweights to prevent power failure and sliding.

Temperature control:

When running under high load or high speed, monitor the temperature rise (can be measured by thermal simulation or infrared temperature measurement), and add heat dissipation measures if necessary.

4. System integration and intelligent control

Closed-loop feedback system:

Use grating scale or magnetic scale to achieve full closed-loop control and compensate for the backlash and thermal deformation error of the lead screw.

Software compensation:

Optimize dynamic response through PID parameter setting, or use feedforward control to reduce following error.

Perform software compensation for the lead screw pitch error (the error curve needs to be measured in advance).

Multi-axis collaboration:

In multi-axis systems (such as XYZ platforms), interpolation motion is achieved through motion controllers to improve overall trajectory accuracy.

5. Regular maintenance and life management

Wear monitoring:

Regularly check the wear of the nut (such as changes in ball diameter or guide rail slider clearance).

Use vibration sensors or noise analysis to predict faults (abnormal vibration may indicate ball damage).

Replacement strategy:

The life of a ball screw is usually calculated based on the rated stroke life (L10), and it should be replaced in time after reaching the life.

Keep key spare parts (such as nut assemblies, support bearings) to reduce downtime.

Environmental adaptation:

In humid or corrosive environments, stainless steel materials or surface coatings (such as chrome plating, nickel plating) are selected.

Heat-resistant materials (such as PPS resin retainers) or load rates can be selected for high-temperature environments.

6. Extended applications for special scenarios

Composite functional design:

Integrated force sensors achieve precise force control (such as precision assembly, medical equipment).

Combined with linear motors to form a hybrid drive system, taking into account high speed and high thrust.

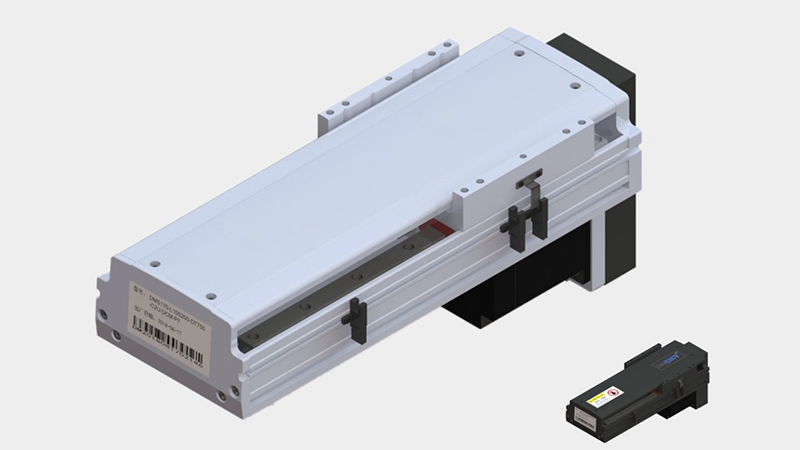

Modular design:

Standardized screw modules are used to support rapid changeover (such as changing the lead or length to adapt to different tasks).

Example: High-speed and high-precision scenario optimization solution

1. Selection: C5-level ball screw + servo motor + linear guide.

2. Installation: Fixed support at both ends, pre-stretching to eliminate the influence of thermal elongation.

3. Control: Full closed-loop feedback + feedforward control, acceleration and deceleration time is set to 0.2 seconds.

4. Maintenance: Replace grease every 500 hours and check preload every 2000 hours.

Through the above measures, the performance, accuracy and life of the screw module can be significantly improved, and efficient application can be achieved in industrial automation, semiconductor equipment, precision measurement and other fields.

← Prev Post