Solution

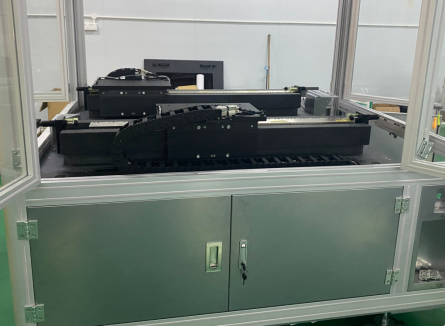

With the continuous development of the manufacturing industry, linear motor modules are being increasingly applied across various sectors. However, as production applications mature, the market's demands for linear motor modules have become more stringent, such as requiring faster delivery times and stricter cost control. It is in this context that Bozhida has introduced the BZD series linear motor modules to meet these market demands.

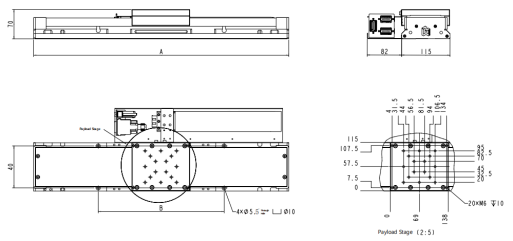

The BZD series linear motor modules mainly consist of a linear motor, mechanical guide rail, encoder for position feedback, and protective housing. Notably, aside from the connection of the guide rail, there is no contact between the other mechanical components. The motor directly drives the module's mover along the guide rail's direction, with position control achieved through the encoder and photoelectric system.

| Platform Model | BZDM115LS-50 | BZDM115LS-100 | BZDM115LS-150 | BZDM115LS200 | BZDM115LS-250 | BZDM115LS-300 |

| Effective Stroke | 50 mm | 100 mm | 150 mm | 200 mm | 250 mm | 300 mm |

| Positioning Accuracy | ±0.75 um | ±1 um | ±1um | ±1.5 um | ±1.5um | ±1.5 um |

| BidrectionalRepetitive Positioning Acauracy | ±0.4 um | ±0.4 um | ±0.4 um | ±0.5 um | ±0.5 um | ±0.5um |

| Pitch Angle | 5 arc sec | 6 arc sec | 8 arc sec | 10 arc sec | 11 arc sec | 12 arc sec |

| Yaw Angle | 5 arc sec | 6 arc sec | 8 arc sec | 10 arc sec | 11 arc sec | 12 arc sec |

| Roll | 5arc sec | 6 arc sec | 8 arc sec | 10 arc sec | 11 arc sec | 12 arc sec |

| Straightness | ±1.5 um | ±2.5 um | ±3 um | ±4 um | ±5um | ±6 um |

| Resolution | 1nm | |||||

| Maximum Acceleration | 3g | |||||

| Maximum Speed | 2m/s | |||||

| Maximum Horizontal Load | 40 KG | |||||

| Maximum Radial Load | 40 KG | |||||

| Continuous Thrust | 26 N | |||||

| Peak Thrust | 144N | |||||

| Minimum Step Size | 20 nm | |||||

| Platform Mass | 5.1 kg | 5.7 kg | 6.2 kg | 6.8 kg | 7.4 kg | 8.1 kg |

| Platform Material | Aluminum | |||||

| MTBF | 20000 Hours | |||||

The advantages of the BZD series linear motor modules lie in their high responsiveness, high precision, high rigidity, long lifespan, high speed, and cost-effectiveness. Since the motor is directly driven, there is no concern about backlash from a lead screw, which significantly improves response speed. Depending on the encoder used, it can achieve a repeatability accuracy of up to ±1μm. The use of mechanical linear guide rails ensures high rigidity across all guiding surfaces. Apart from the contact between the guide rail sliders, there is no other mechanical contact, reducing the risk of module damage caused by mechanical wear. Additionally, the DGC series can meet speed requirements of 3m/s or higher.

The use of a profile design greatly reduces machining complexity and material costs, while the standardized design lowers production costs for common parts. The company owns its own machining facility and maintains stock of common components, ensuring quick delivery times.

The BZD series linear motor modules have been widely applied in industries such as photovoltaics, lithium batteries, semiconductors, 3C automation, LCD panels, and optical inspection. They not only provide customers with high-quality products but also effectively reduce production costs and improve overall efficiency. This cost-effective linear motor module is ideal for industries requiring high-speed, high-precision positioning, making it the preferred solution for many customers.

← Prev Post

Next Post →