What are the advantages of high-precision moving beam gantry over traditional gantry?

2025-04-15

High-precision moving beam gantry machine tools have significant advantages in structural design, precision, dynamic performance and application scenarios compared to traditional gantry machine tools (such as fixed beam or moving column gantry). The following is a comparative analysis of the main advantages

1. Structural design and rigidity optimization

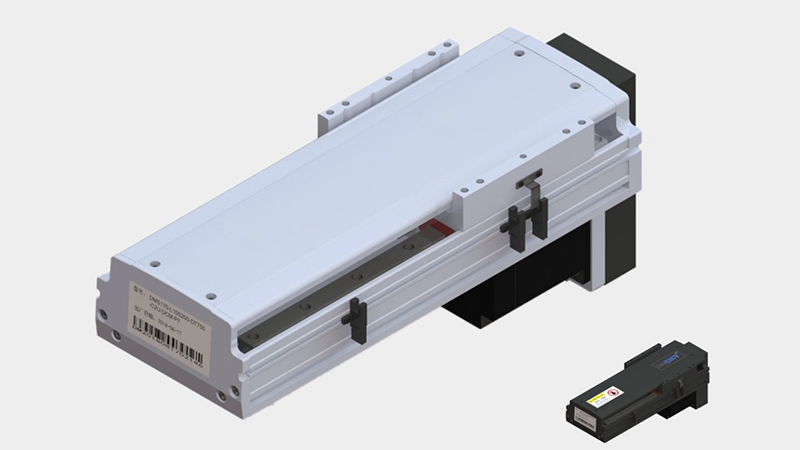

Moving beam structure: The beam can move up and down along the column, and the worktable is fixed or only moves simply, which reduces the load on the worktable and is suitable for processing oversized or heavy workpieces.

High rigidity design: By optimizing the cross-sectional shape of the beam and column (such as box structure, honeycomb structure), and matching high-performance materials (such as polymer concrete, cast iron), the vibration resistance and thermal stability are stronger, which is suitable for high-precision processing.

Symmetrical dual-drive system: The beam movement is usually driven by double-sided servo motors + roller screws/linear motors, with high synchronization accuracy to avoid tilt errors caused by eccentric loads.

2. Processing accuracy and stability

Precision retention: The moving beam structure reduces the inertial impact caused by the movement of the worktable and reduces the accumulation of geometric errors (such as guide rail wear and positioning drift).

Thermal deformation control: High-precision models are usually equipped with temperature compensation systems and cooling technologies (such as screw hollow cooling) to reduce the impact of thermal displacement on processing accuracy.

Micron-level accuracy: Using high-resolution grating scales and laser feedback systems, the positioning accuracy can reach ±0.003mm/m, and the repeat positioning accuracy can reach ±0.002mm, which is suitable for precision molds and optical components processing.

3. Dynamic performance and efficiency

- High speed and high acceleration: The moving parts of the moving beam structure have low mass. When driven by a linear motor, the fast moving speed can reach 60-100m/min and the acceleration is 1-2g, which improves processing efficiency.

- Large stroke coverage: The vertical movement of the beam extends the Z-axis stroke, and there is no need to frequently adjust the workpiece clamping, which is suitable for complex curved surfaces or multi-process processing.

- Reduce idle travel time: The worktable is fixed or only moves horizontally, and the moving beam is quickly positioned to shorten the non-cutting time, which is especially suitable for batch processing of multiple workpieces.

4. Application scenario expansion

- Processing of super-large workpieces: The moving beam structure can be adapted to super-wide workbenches (such as more than 10 meters), without moving heavy workpieces, reducing the difficulty of clamping.

- Five-axis linkage capability: The moving beam gantry is easier to integrate with a swing head or a rotary table to achieve complex curved surface processing (such as aerospace structural parts, impeller blades).

- Automation compatibility: The fixed workbench is easy to integrate robots or automatic material warehouses, and is adapted to flexible manufacturing cells (FMC) or unmanned production lines.

5. Compensation for the disadvantages of traditional gantry (fixed beam type/moving column type)

Limitations of traditional gantry:

- Fixed beam type: The workbench has a large moving load and high inertia, which affects high-speed performance.

- Moving column type: The movement of the column leads to a decrease in rigidity, which is suitable for small and medium-sized workpieces, and it is difficult to process super-large parts.

- Improvements of the moving beam gantry:

- Take into account large stroke and high rigidity, and balance precision and efficiency.

- More suitable for mass production of high value-added and high-complexity workpieces.

The core advantage of high-precision moving beam gantry lies in the collaborative ability of "large size + high precision + high dynamics", which is especially suitable for high-end processing needs in the fields of aerospace, energy equipment, precision molds, etc. Traditional gantry still has cost advantages in small and medium-sized workpieces or low-precision scenarios, but when facing ultra-precision and ultra-large workpieces, moving beam gantry is a better choice.