BZD Robotics | Covering all industries, provider of precision operation and control solutions

2025-04-12

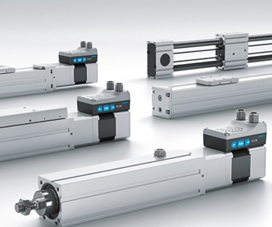

Automation equipment plays a vital role in the manufacturing industry. They not only improve production efficiency, but also ensure production quality and safety. Bozhida Robotics provides systematic solutions for the comprehensive localization of automation, from linear motor R&D and production, marble platform factories, to high-end assembly workshops, from design selection to delivery and commissioning, providing customers with one-stop services.

博智达机器人

Headquartered in the coastal city area of Shajing, Shenzhen, based in the Greater Bay Area, it provides linear motion solutions for global customers. Its core businesses include linear guides, telescopic guides, linear modules and linear module integrated systems for different industries.

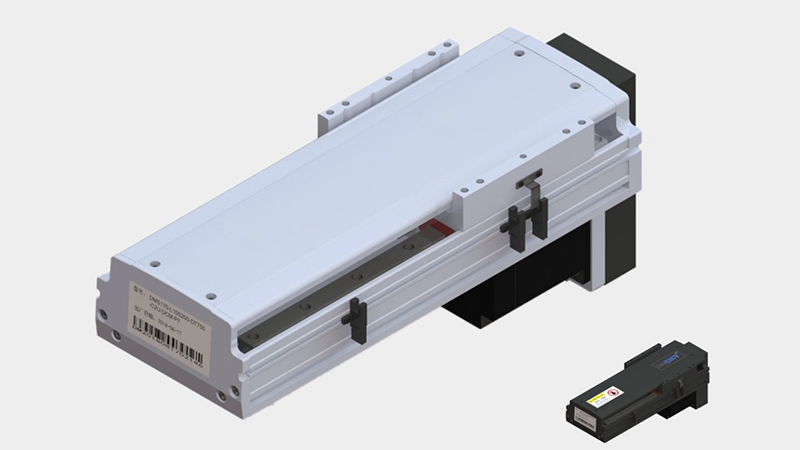

Using high-tech testing equipment and high-quality materials, it independently develops and produces high-end linear motors, linear motor platforms, DD motors, voice coil motors and other reliable linear drive equipment, reaching the performance indicators of foreign counterparts, and can be tailored according to customer needs, customized high-end drive platforms, and one-stop solutions for customer drive problems.

It is widely used in electronic and semiconductor equipment, UV inkjet industry, UV printing and dyeing industry, UV printing industry, UV glass industry, precision CNC machine tools, high-end medical equipment, mobile phone testing industry, glass testing industry and other fields. At present, the company is a second-tier supplier of Apple mobile phones, and has in-depth cooperation with China High-speed Railway South Locomotive (Zhuzhou), Shenzhen Aerospace Science and Technology Research Institute and Harbin Institute of Technology (Shenzhen) Research Institute.

Huizhou Factory-Marble Platform

02

Bozhida Robotics has its own granite (hereinafter referred to as marble) platform processing factory. Marble is the first choice for the base of industrial equipment, and linear drive equipment cannot do without marble platform. We set up the factory in Huizhou, near Shenzhen, with convenient transportation.

At the same time, the masters of our factory are all from Qingdao Qianshao, a large state-owned enterprise directly under the Ministry of Aerospace of China. They have more than 20 years of experience in marble production and processing and master advanced production and processing technology. There are many large-scale assembly cases, including large-scale projects such as CRRC Torsion Bar, Matrix Measuring Instrument of Chinese Academy of Sciences, and Simulation Vehicle of Nanjing University of Aeronautics and Astronautics.

South China Assembly Base-Constant Temperature Workshop

03

The positioning accuracy and resolution of precision and high-precision motion platforms are mostly sub-micron, and the influence of the working environment cannot be ignored. Temperature changes directly affect the positioning accuracy of the platform, external vibrations affect the stability of the system, and changes in ambient temperature and humidity affect the accuracy of the sensor. In order to produce high-quality precision equipment more quickly and accurately, Bozhida Robotics has set up a Bozhida South China assembly base to reduce errors and failures.

High-standard constant temperature and humidity workshop: Generally, temperature and humidity changes should be controlled within 20±0.1℃, and humidity should be controlled within 50%±5%. For platforms with higher precision, temperature changes should be controlled within 20±0.1℃. In order to achieve the minimum temperature change, multi-level constant temperature workshop nesting measures are adopted to ensure the accuracy of the delivered platform. After delivery to customers, adjustments are reduced and put into use as soon as possible.