Linear module manufacturers explain several commonly used structural modes

2025-04-12

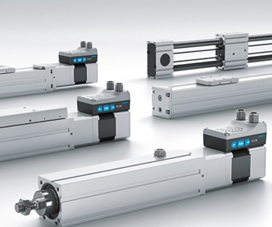

The linear module manufacturer explains several commonly used structural modes. With the popularization of industrial automation technology, more and more companies are adopting mechanical intelligence, from unmanned supermarkets to unmanned convenience stores, which are being introduced step by step. Perhaps one day, machines will replace manual labor. From a long-term perspective, this is a major trend in the future. If you don't want to be eliminated, you can only make continuous progress. In the first half of the year, we entered the new product research and development stage and began to specialize in linear modules, linear modules, screw modules, and other robot parts.

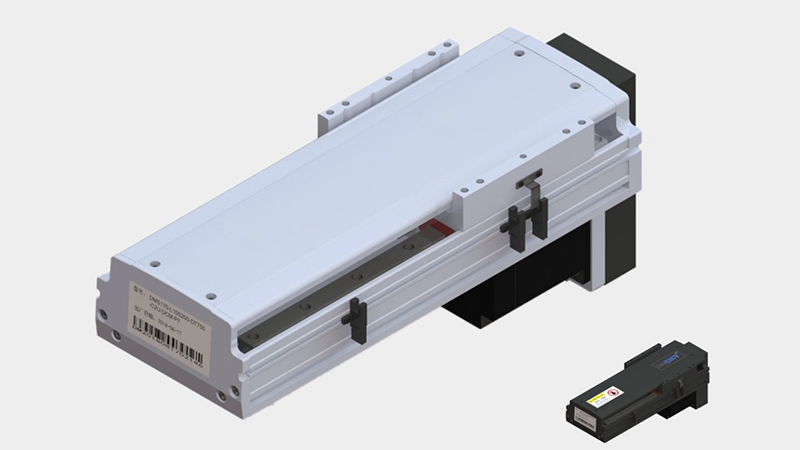

Speed reduction mechanism: Increase the output thrust of the slide and save the overall space of the slide.

High-strength steel wire synchronous belt: low dust generation, high tension.

Integrally enclosed slide frame: reliable strength and beautiful appearance.

Precision linear guide: ensure the straightness and parallelism of the sliding operation.

Sensor wire slot: the sensor cable can be built-in to prevent damage to the sensor and cable.

Split motor connector: strong interchangeability facilitates the installation of couplings and motors.

Seals: prevent grease from overflowing and dust from entering.

Integrally enclosed slide frame: reliable strength and beautiful appearance.

Precision linear guide: ensure the straightness and parallelism of the sliding operation.

Sensor wire slot: the sensor cable can be built-in to prevent damage to the sensor and cable.

Precision ball screw: C5 and C7 are optional.

Various input connection methods

Without changing the length of the mechanical body, various connection methods of the manipulator input can be realized, with strong interchangeability.

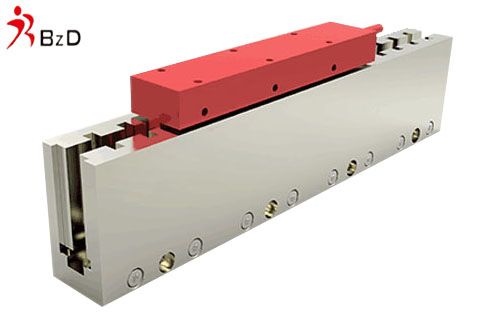

Characteristics of clean type manipulator

Vacuum pipe joint: vacuum pipe can be connected in dust-free environment to suck out the trace dust generated by mechanical friction inside the module.

Sealing strip: rubber magnet sucks the steel belt to prevent the steel belt from deforming and bulging, so as to achieve effective sealing.

Dust-free environment manipulator (the standard configuration does not install sealing strips. The installation of sealing strips will generate trace dust in the dust-free environment, so sealing strips are generally not installed. If the customer needs it, please explain it before ordering the product.)

Steel belt, rubber roller: wear-resistant rubber roller is used at the contact point between the manipulator slide and the steel belt to achieve rolling friction between the slide and the steel belt, reduce the resistance between the slide and the steel belt, prevent the generation of friction dust, and reduce noise.

Linear module manufacturers explain several commonly used structural modes. Through the above detailed overview, I believe that everyone has a certain understanding of linear modules and has different opinions. What are the specific performance and efficiency? You will know it in the subsequent use process. If you have any questions in this regard, you can call our company at any time!

The above is a detailed introduction to "Several commonly used structural modes explained by linear module manufacturers". For more information, please pay attention to other information on the official website of Bozhida Linear Motor!