Application

See what project success looks like

Our customers sound off on what it was like to work with us on their metrology challenges.

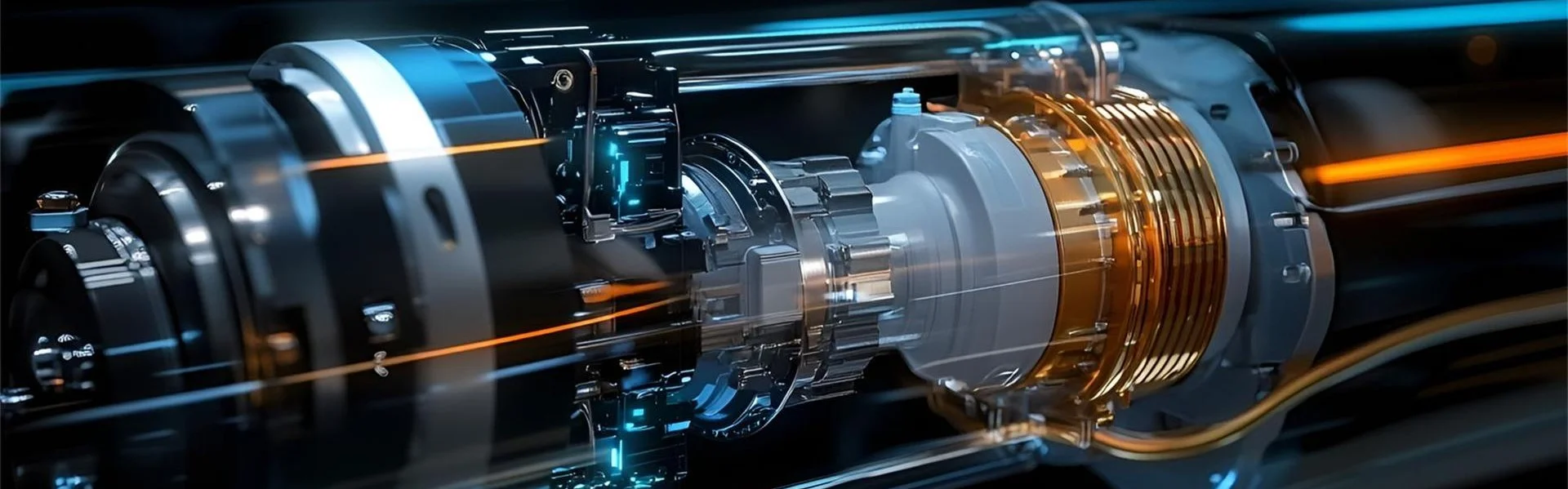

Project

Semiconductor Manufacturing

Photolithography machine: used for nano-scale chip pattern exposure, linear motors achieve ultra-high precision synchronous positioning of the mask stage and wafer stage. Wafer inspection and bonding: high-precision platforms ensure micron-level positioning during wafer defect inspection, cutting and packaging.

High-speed dynamic response and high stability

Compact structure and modular design

Energy efficiency optimization and intelligent integration

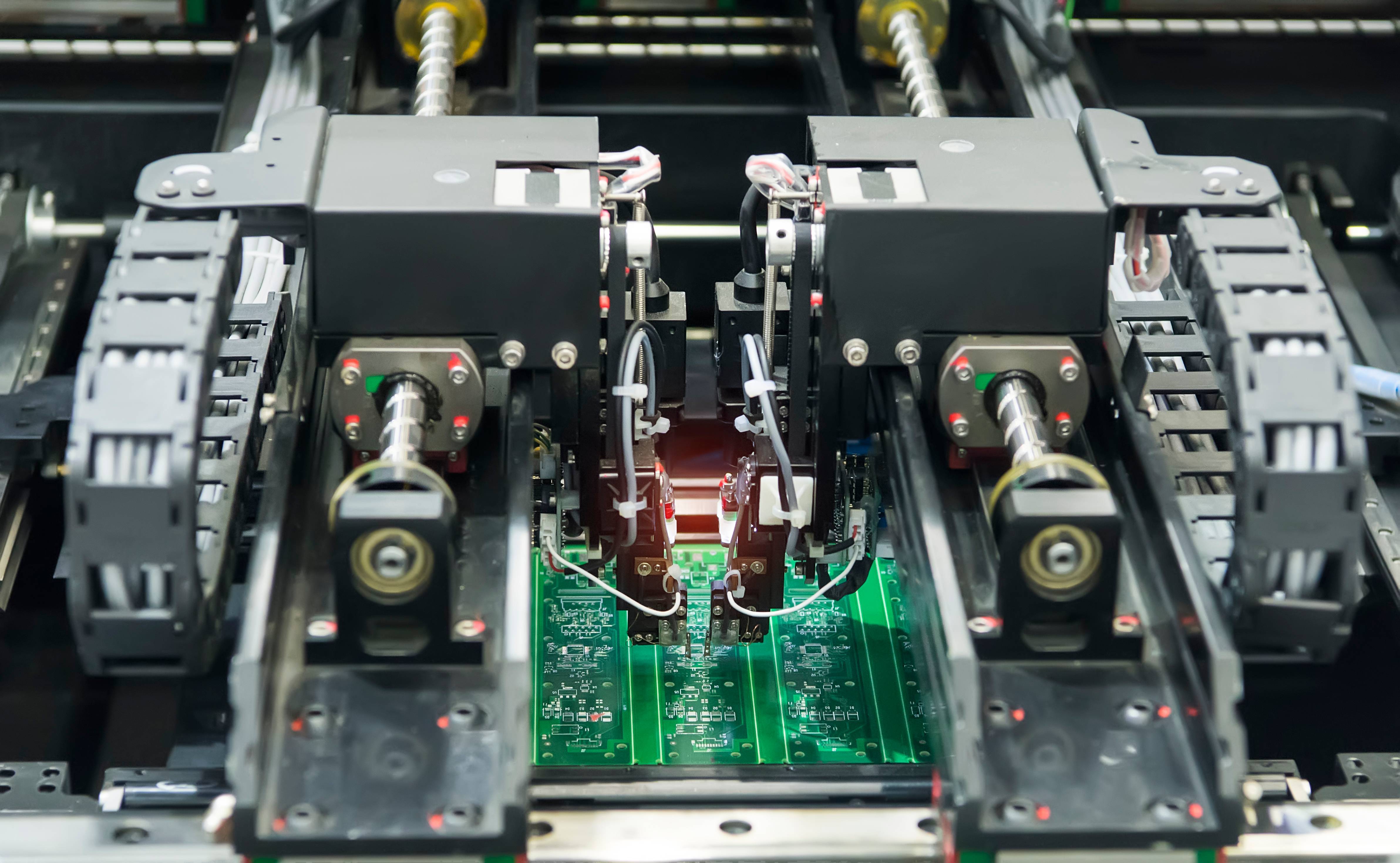

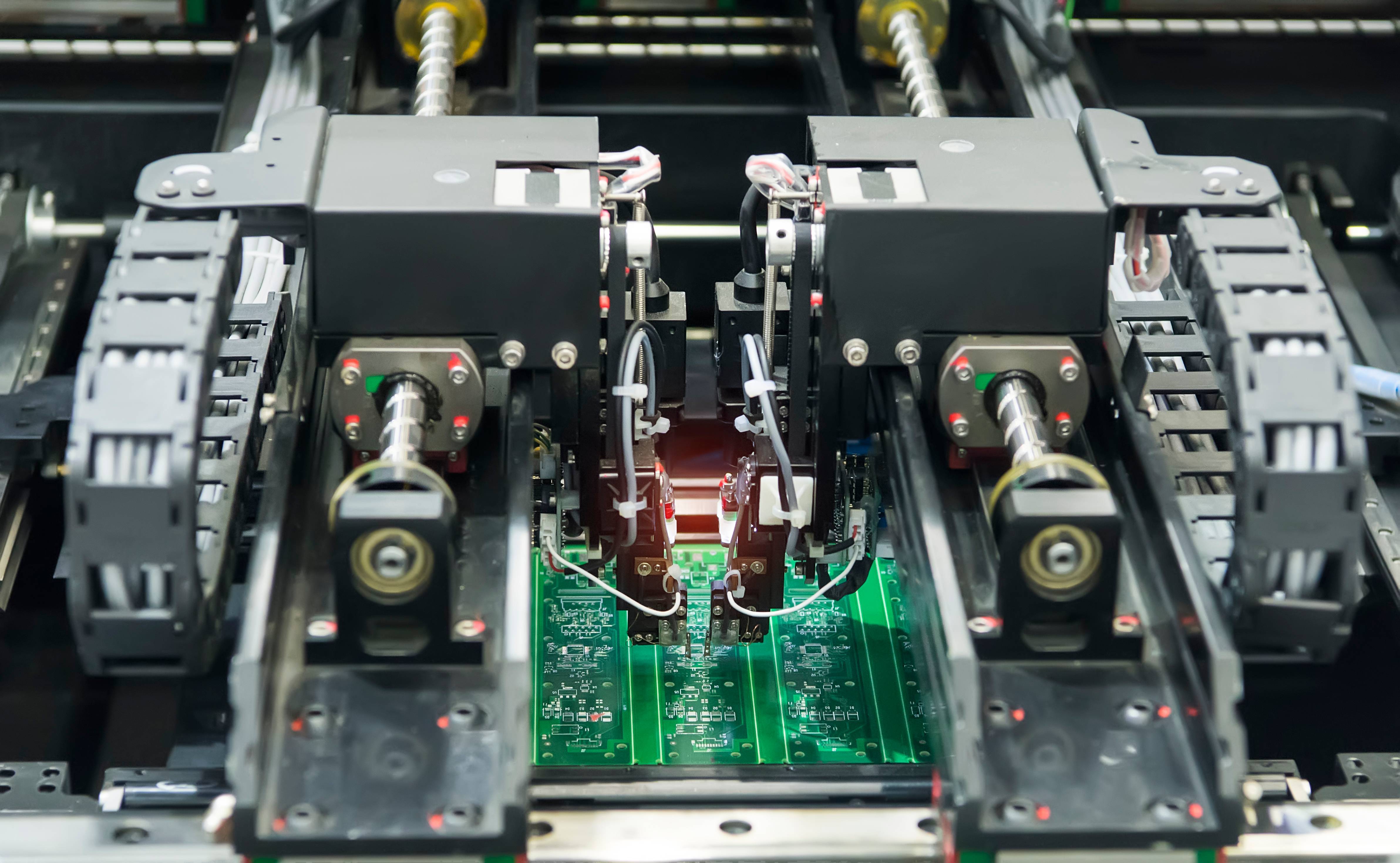

Project

Electronics Manufacturing

SMT placement machine: Linear motor drives the nozzle to place electronic components on the PCB at high speed and precision. PCB drilling and cutting: Precision platform realizes micro-hole processing and laser cutting of multi-layer circuit boards.

Direct drive and high dynamic performance to achieve nanometer-level repeatability

Closed-loop control with linear encoder, positioning accuracy reaches sub-micron level

Integrated laser interferometer feedback and AI algorithm to compensate thermal drift in real time

Project

Precision measurement and testing

Optical microscope/electron microscope: nanometer-level mobile sample stage, supporting ultra-clear imaging of biological samples or material structures. Coordinate measuring machine (CMM): high-precision platform improves the detection accuracy of complex workpiece geometry.

Eliminate backlash, friction and mechanical loss, significantly improve motion accuracy

There is no mechanical contact transmission, and the vibration is extremely small during operation, which reduces the interference to the precision measurement.

Air bearings, magnetic bearings or precision ball guides are used, with high static rigidity and strong resistance to external interference.

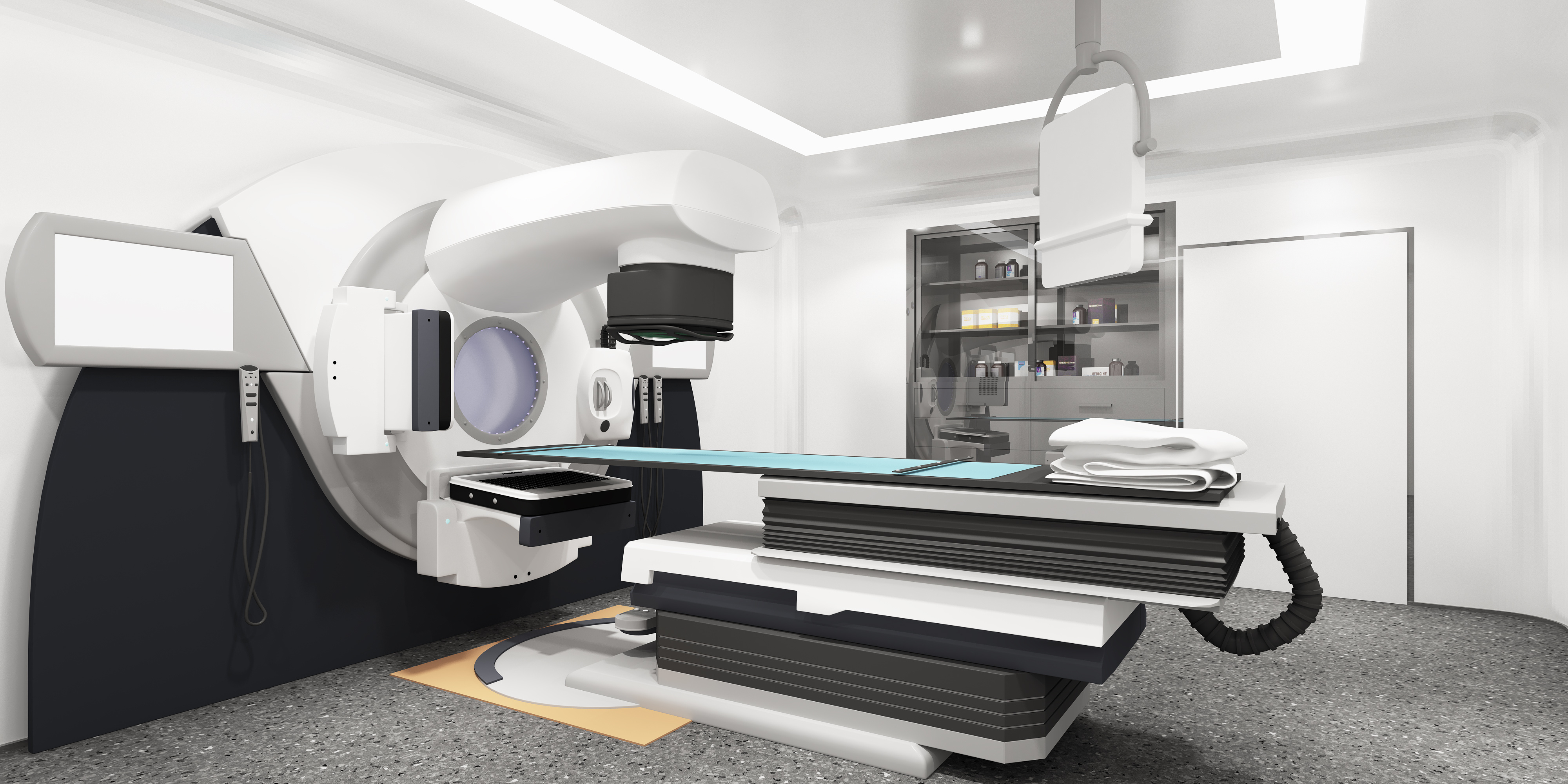

Project

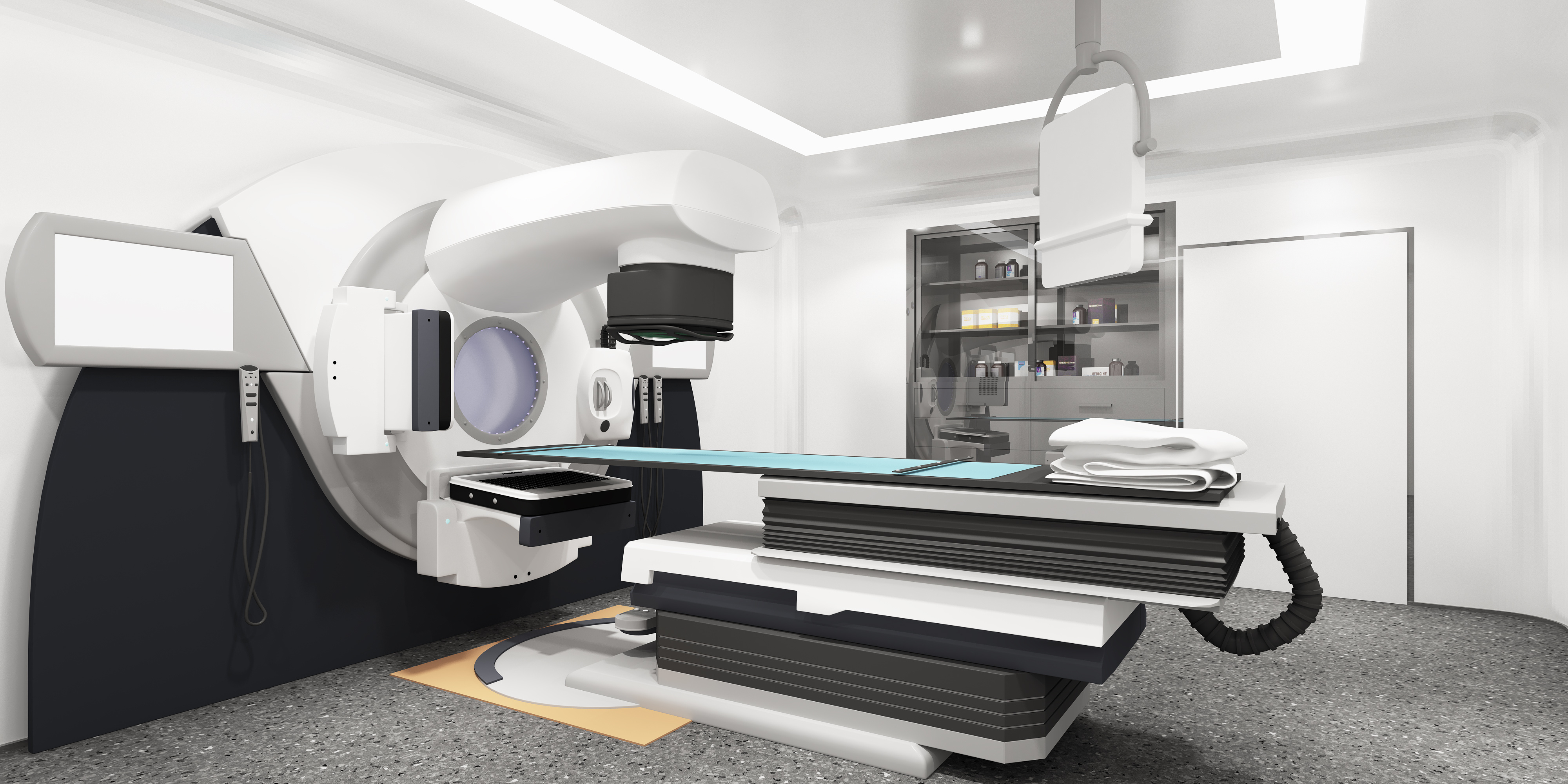

Medical and Biotechnology

Medical imaging equipment (MRI/CT): Linear motors control the smooth movement and precise positioning of the scanning bed. Surgical robots: Such as the da Vinci system, which uses a high-precision platform to achieve sub-millimeter-level operation of minimally invasive surgical instruments.

Magnetic suspension or air flotation technology reduces mechanical wear and is suitable for sterile environments or scenarios that require long-term stable operation.

Modular design allows integration into compact devices and supports multi-DOF motion.

Significantly improved the efficiency and safety of medical diagnosis, surgical operations and biological experiments

Project

Automated processing and 3D manufacturing

Laser processing (cutting/welding): Linear motors enable high-speed, high-precision laser head path control. 3D printing/additive manufacturing: Precision platforms ensure inter-layer positioning accuracy during material deposition or photocuring.

High speed and high dynamic response, acceleration can reach more than 10g, speed exceeds 5m/s, suitable for fast start and stop and frequent switching scenes

Low thermal expansion materials combined with real-time temperature compensation algorithms ensure long-term processing stability

The sealed design is anti-sit and splash-proof, and the anti-electromagnetic interference design is compatible with strong magnetic field scenarios

Project

Scientific research and high-end equipment

Particle accelerator: Linear motor drives particle beam control components to achieve sub-micron adjustment. Astronomical telescope: Precision platform adjusts the mirror or detector position to compensate for atmospheric disturbances or mechanical errors.

High precision and low vibration, sub-micron or even nanometer repeatable positioning accuracy can be achieved under closed-loop control, without mechanical contact wear and good long-term stability

It can be designed as a multi-axis linkage system (such as an XY stage), or combined with an air-floating/magnetic-floating guide rail to achieve frictionless motion, suitable for harsh environments such as vacuum and clean rooms

Can be designed as a multi-axis linkage system (such as XY0 platform), or combined with air suspension/magnetic suspension guide rails to achieve frictionless motion

Application Field

Our expertise across and deeply within many industries gives us a solid foundation for building a reliable and successful motion control solution that meets your specific needs.

Semiconductor Manufacturing

Photolithography machine: used for nano-scale chip pattern exposure, linear motors achieve ultra-high precision synchronous positioning of the mask stage and wafer stage. Wafer inspection and bonding: high-precision platforms ensure micron-level positioning during wafer defect inspection, cutting and packaging.

Electronics Manufacturing

SMT placement machine: Linear motor drives the nozzle to place electronic components on the PCB at high speed and precision. PCB drilling and cutting: Precision platform realizes micro-hole processing and laser cutting of multi-layer circuit boards.

Precision measurement and testing

Optical microscope/electron microscope: nanometer-level mobile sample stage, supporting ultra-clear imaging of biological samples or material structures. Coordinate measuring machine (CMM): high-precision platform improves the detection accuracy of complex workpiece geometry.

Medical and Biotechnology

Medical imaging equipment (MRI/CT): Linear motors control the smooth movement and precise positioning of the scanning bed. Surgical robots: Such as the da Vinci system, which uses a high-precision platform to achieve sub-millimeter-level operation of minimally invasive surgical instruments.

Automated processing and 3D manufacturing

Laser processing (cutting/welding): Linear motors enable high-speed, high-precision laser head path control. 3D printing/additive manufacturing: Precision platforms ensure inter-layer positioning accuracy during material deposition or photocuring.

Scientific research and high-end equipment

Particle accelerator: Linear motor drives particle beam control components to achieve sub-micron adjustment. Astronomical telescope: Precision platform adjusts the mirror or detector position to compensate for atmospheric disturbances or mechanical errors.