Ring linear motor

· Each linear motor independent control · Each linear motor adopts different acceleration and deceleration speed and curve control, which can facilitate the production of buffering. · Annular guide rail and slide seat can be made into runway type or rectangle.

- Product Detail

- Technical parameter

- Product characteristics

- File Download

-

Precision grinding of the ring guide, linear motor can follow the precise trajectory of the cycle movement. Circulation conveying line, a good combination of annular guide rail and linear motor, can achieve ultra-high circulation conveying efficiency, greatly shorten the production time.

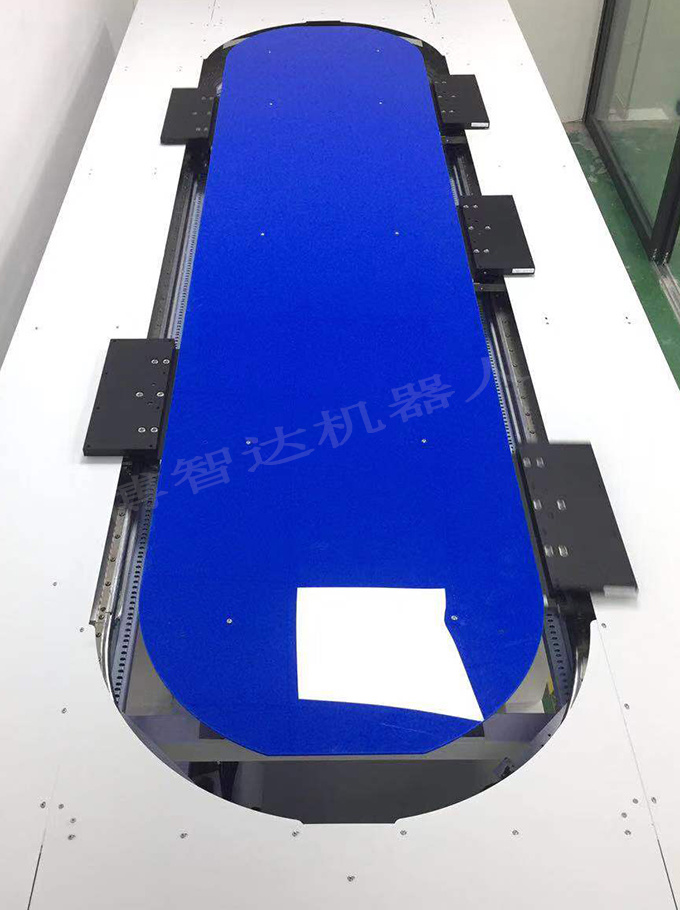

As shown in the figure below, the linear motor is not a normal linear motor, but a linear motor that can be turned to do circular motion and achieve closure, which can be called a circular linear motor; The stator consists of a coil, fixed on the base of the equipment, and generates a magnetic field after being energized. The actuator is installed on the slide seat and is a permanent magnet; The permanent magnet on the sliding block is pushed by the magnetic field generated by the induction coil of the stator, and the sliding block moves along the guide rail. The basic principle is similar to maglev. The actuator on the slide seat is a permanent magnet, which does not require power supply to generate a magnetic field, and there is no power line, so the slide seat can do infinite cyclic motion:

The linear motor is located above the ring guide rail, and the bottom of the car is equipped with a roller, which is matched with the ring guide rail; The upper part of the car is equipped with a actuator, which is matched with the stator of the linear motor to provide power.

The linear motor is located above the ring guide rail, and the bottom of the car is equipped with a roller, which is matched with the ring guide rail; The upper part of the car is equipped with a actuator, which is matched with the stator of the linear motor to provide power.

A big advantage of the ultra-efficient cycle line is that each car is independently controlled, equivalent to an independent servo motor, which can be independently programmed to set the acceleration and deceleration curve of the car, and different cars can adopt different acceleration and deceleration curves; It can easily realize the buffering function in automatic production. If you need to change the process sequence, you only need to change the program Settings through software, without the need to modify and change the mechanical mechanism.

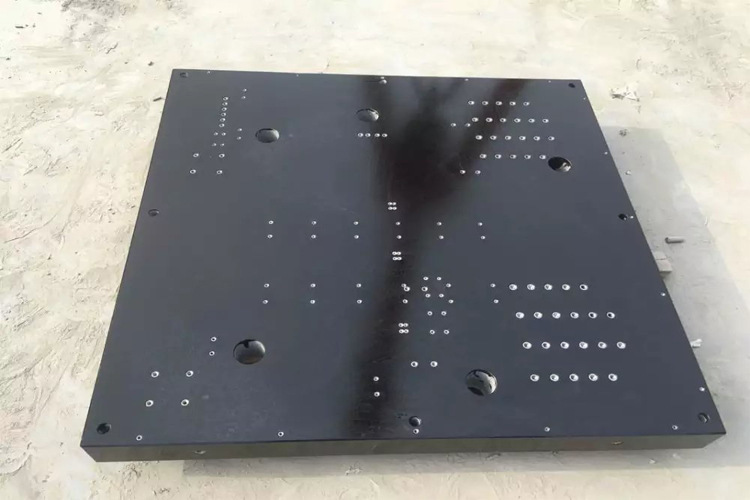

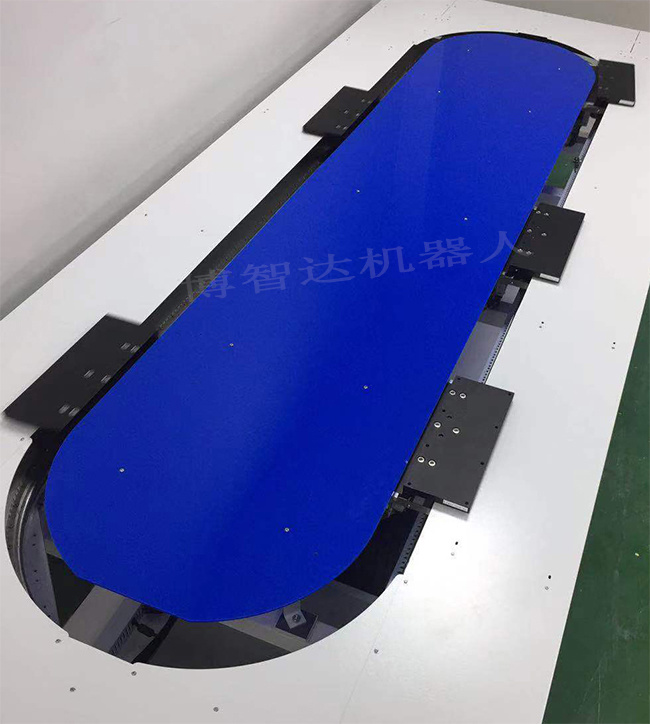

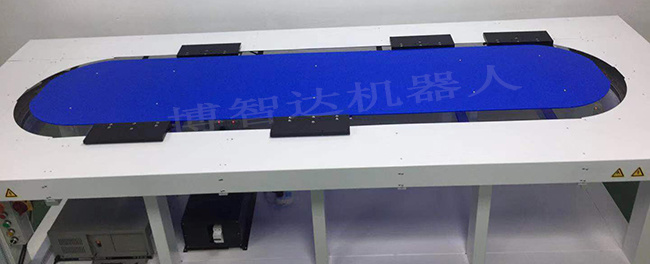

The core mechanical components of the whole system are the annular guide rail and slide seat shown in the figure below, which can be made into a runway type or a rectangle:At the same time, we can also provide a complete set of mounting bases to facilitate the installation of rail and magnetic levitation motor systems:

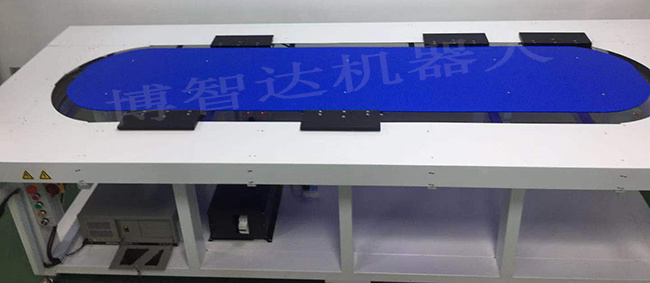

After installation, the overall product is shown as follows:

-

· Each linear motor independent control

· Each linear motor adopts different acceleration and deceleration speed and curve control, which can facilitate the production of buffering.

· Annular guide rail and slide seat can be made into runway type or rectangle.

Related Products